Want to know the specifics of each roof material?

While we install all types of manufactures, the example below is for Atlas, our preferred asphalt shingle roofing system, and the other items that go into your system.

ROOF MATERIALS WE USE:

Synthetic Underlayment:

- Atlas Summit 60

- Install over entire roof surface

- Installed using 1″ plastic cap nails

- 10 squares per roll

Rather than installing 15 or 30 # felt, we install synthetic underlayment which provides enhanced protection against water and mold growth, and is made with a woven polymeric scrim which reduces slippage between underlayment and roof decking, and is safer for the crew to walk on during installation. Synthetic underlayment can keep the roof water tight without shingles on top for up to 60 days.

Ice & Water Shield:

- Atlas WeatherMaster Ice & Water 200

- Install in all valley’s, base of roof flashing, and perimeter of chimney.

- Self adhering installation

- 66 LF per roll

Rather than installing metal in the valley of the roof we install ice and water shield. When you drive a nail through metal there is a small gap around the nail head where water can enter, but ice and water shield is a rubberized membrane which creates a watertight barrier by sealing around the nails when punctured. This provides a secondary waterproofing barrier in leak prone areas to prevent ice dams and damage from wind blown rain.

STARTER STRIP:

Atlas Pro-Cut Starter Strip

- Installed around the full perimeter of roof line after underlayment, before shingles.

- Installed using 1.25″ galvanized roofing coil nails and 140 LF per bundle.

Rather than flipping a 3-tab shingle upside down, we install a true starter strip which has an extra layer of adhesive known as the “seal down strip” which enhances wind resistance for bottom roof of shingles to prevent shingles from lifting up during high winds.

Shingles:

- Atlas Pinnacle Pristine High Performance Architectural Shingles

- Install in field of roof surface with pitch 3/12 or higher

- Installed using 1.25″ galvanized roofing coil nails.

- 3 bundles per square

Rather than installing 3-tab shingles which have 60 mph wind resistance and a 25-year manufacture warranty, we install Atlas Pinnacle Pristine architectural shingles which have 130 mph wind resistance and a 50-year manufacturer’s warranty. 3M Scotchgard produces copper granules for the Pinnacle Pristine shingles and the granules on the shingles are comprised of approximately 12% copper which keeps the roof algae free for the lifetime of the shingle. Atlas is one of 2 manufactures that can provide lifetime algae resistance warranty (other is Malarkey.) Atlas has an industry leading 50 year non-prorated manufacture warranty, and only requires 4 nails per shingle for 130 mph wind resistance (competitors require 6 – Atlas has less penetrations back through the roof deck and less chance of leaks.) Nail strip is 1.5″ which provides installers enough space to hit nail strip each time to achieve intended wind resistance.

Hip & Ridge Cap:

- Atlas Pro Cut Hi Profile Hip & Ridge Shingles

- Install on all hips/ridges on roof line

- Installed using 1.25″ galvanized roofing coil nails.

- 20 LF per box

Rather than cutting 3-tab shingles and using them for hip/ridge, we install hi-profile hip/ridge caps which are thicker, have a higher wind resistance and provide a designer appearance. 3-tab hip/ridge caps only have 60 mph wind resistance and a 25 year warranty period, while hi-profile hip/ridge caps are 130 mph wind resistant and are covered by the Atlas 50-year Lifetime Manufacturer’s Warranty.

Drip Edge Flashing:

- 1.5″ x 1.5″ galvanized metal drip edge (standard)

- Install around full perimeter of the roof line (eaves & rakes)

- Install using 1″ cap nails

- 10 LF per piece

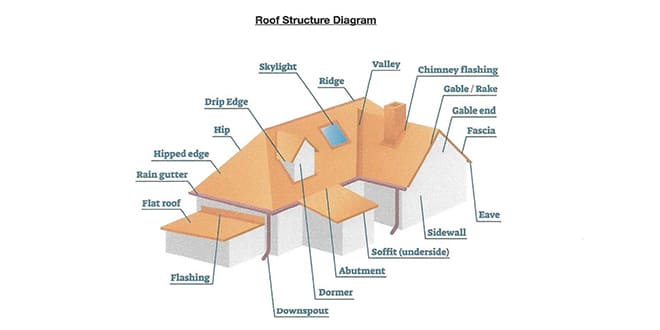

We install drip edge flashing around the full perimeter of the roof line to prevent water trickling off of the shingle, and being absorbed by the wood fascia trim. Drip edge is metal flashing bent at a 90 degree angle that gets installed on all eaves/rakes of the roof line by a cap nail on the top side of the flashing that sits flush on top of the roof decking. The front side of the flashing should sit flush on the front of the fascia board. We also install drip edge with a pre-baked paint finish that matches the color of the shingles.

Pipe Jack Flashings:

- Galvanized Steel 3N1 Pipe Flashing

- Install on plumbing exhaust vents (pipe jacks)

- Install using 1.25″ galvanized roofing coil nails

Rather than using plastic pipe jack flashing’s that crack due to high heat in Texas, or lead pipe jack flashing’s that squirrels chew on (create hole), we use 3N1 pipe jack flashing’s that have a galvanized steel base, and an elastomeric collar. Once the flashings are installed we caulk/seal the nails and paint them to match the shingle color for aesthetics.

Roof Exhaust Vents:

The purpose of roof exhaust vents is to allow hot air to escape the attic. A cool/properly ventilated attic space will help the shingles last longer, and will reduce the amount of energy needed to keep the inside of the home a cool/comfortable temperature. A improperly ventilated attic space will reduce the life of the shingles and will require more energy to keep the inside of the home cool/comfortable. When the attic is under-ventilated it is like an oven – the high temperature in the attic causes the asphalt on the shingles to bubble, and eventually the bubble will burst and leave a small hole in the shingle (blistering) which can allow water to enter the attic/home. Regardless of which type of vent you install, the attic exhaust and intake need to be matched for proper ventilation. In order to match the intake/exhaust you should use a vent calculator to verify how many intake/exhaust vents are needed (GAF’s website has a great/free attic vent calculator you can use to match the intake/exhaust for different types of vents.)